Helios Industrial

Extremely fast and simple super-polymers printing. PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG, PP and much more

Request information

Extremely fast and simple super-polymers printing. PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG, PP and much more

Request informationThe movement system with ball screws has always been synonymous of repeatability and accuracy. HELIOS guarantees printing precision of 50 microns and high repeatability.

The complete automation of the process reduces manual operations. From the loading of the material to the self-calibration of the plan.

HELIOS reaches high temperatures. The double Hotend allows to extrude materials up to 500 °C. The print bed, with a volume of 600 x 600 x 600 mm (xyz), reaches temperatures on the bed up to 150 °C.

The printer is equipped with a printing chamber heating and ventilation system that can reach 180 °.

This feature allows to print the superpolymers and avoid problems of deformation of the piece and above all it allows to carry out the up / down annealing process in 5 phases for the annealing of the parts.

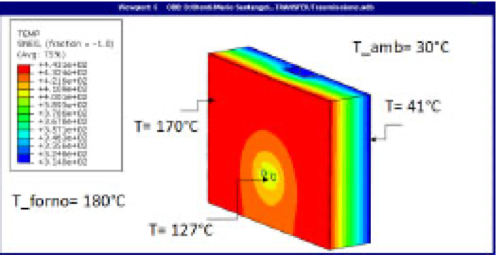

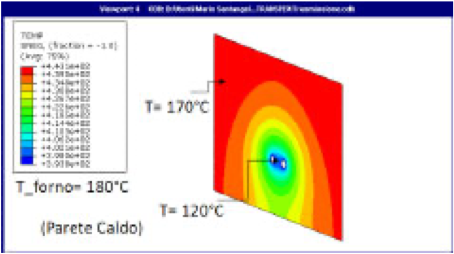

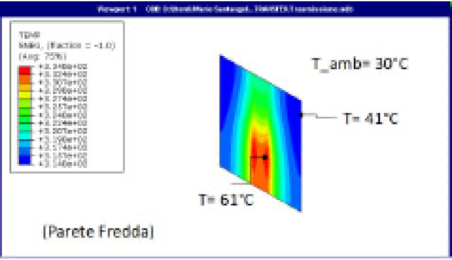

For the optimization of the uniformity of heat distribution inside the chamber and for the dissipation of heat towards the external walls of the machine were carried out analysis using thermo- structural solvers.

The drying system is inside the machine. A front door allows access to the Dryer system where there are 2 slots for the filaments. The filament then pass through the PTFE bowden up to the extruder.

Set the box temperature according to the type of 3D filament, the temperature environment, humidity, etc.

The temperature between 35 and 55 ° C.

It is suitable for more than 20 types of consumable material commonly used inthe market.

The standard continuous drying time is 6 hours, but can be changed in a range from 0 to 24 hours.

HELIOS Dryer has the function of preparing the material before printing, drying and heating it, thus guaranteeing surface quality and mechanical performance of the printed parts.

HELIOS is equipped with stepper motors which are driven by drivers capable of automatically correcting any loss of steps, ensuring precision and repeatability of movement with guaranteed tolerances.

HELIOS is equipped with automatic material loading sensors, end of material detection sensor and detection of possible anomalies, to guarantee total control of the machine status.

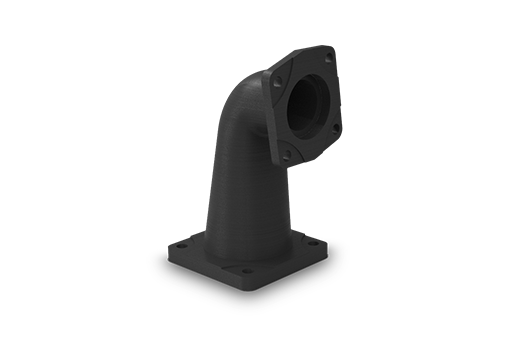

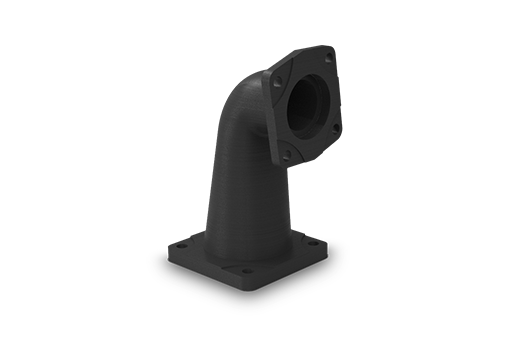

Helios is ideal for printing functional prototypes and finished components, so it handles a large variety of rigid and flexible engineering polymers up to super polymers. Thanks to its flexibility, it allows the creation of production equipment and finished production parts replicated in small series with a saving in terms of costs and time compared to traditional production methods.

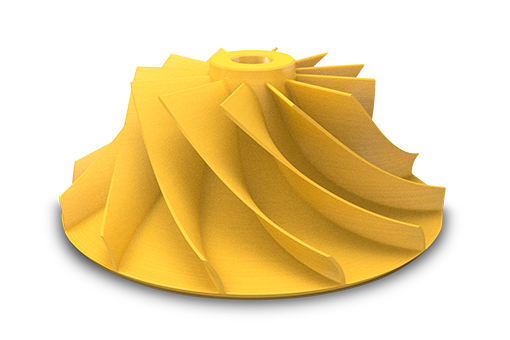

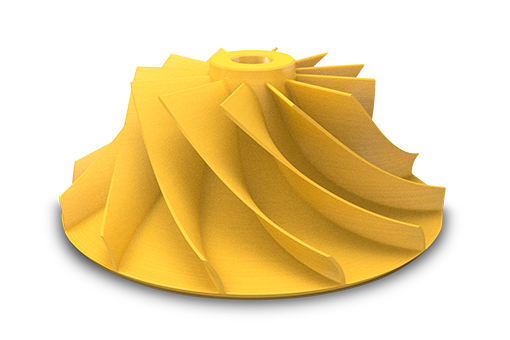

Thanks to the flexibility of Helios, it’s possible to mold components in super polymers and composites (PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG) that have complex geometries such as those required for the Aerospace and Automotive Racing industries. Helios allows to replicate molded components, for a homogeneous production.

Helios is ideal for printing functional prototypes and finished components, so it handles a large variety of rigid and flexible engineering polymers up to super polymers. Thanks to its flexibility, it allows the creation of production equipment and finished production parts replicated in small series with a saving in terms of costs and time compared to traditional production methods.

Thanks to the flexibility of Helios, it’s possible to mold components in super polymers and composites (PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG) that have complex geometries such as those required for the Aerospace and Automotive Racing industries. Helios allows to replicate molded components, for a homogeneous production.

| Technical data | |

| Dimensions of the 3d printer | X = 1000 mm Y = 1200 mm Z = 1700 mm |

| Print volume | X = 600 mm Z = 600 mm Y = 600 mm |

| Precision | 50μm |

| System weight | 280 Kg |

| Printable materials | PEEK, ULTEM, Carbon PA, ABS, NYLON, ULTRA-PLA, PETG |

| Filament size | 1,75mm (on request 2,85mm) |

| Hotend | Double high temperature hotend |

| Nozzle temperature | 500° (for main hotend, 250° for seconday hotend) |

| Print bed temperature | 150° |

| Heated chamber temperature | 180° |

| Electronics | 32-bit |

| Power panic | Automatic print resumption system after a black-out |

| Ethernet connection | WiFi 2,4Ghz |

For all our machines, it’s possible to develop Customized Automation for the part loading and handling part, pallet handling and other customized and unique solutions.

Find how