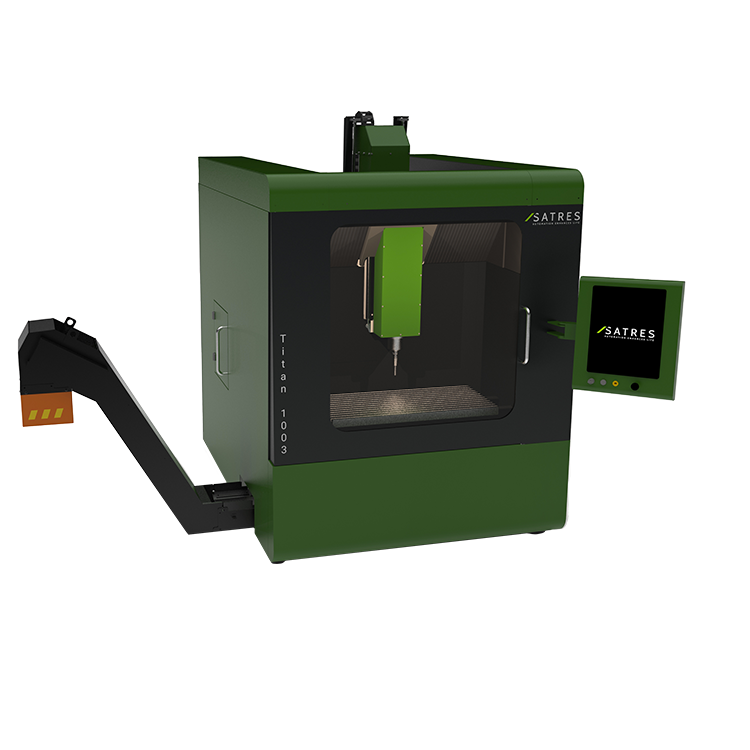

Titan 1003

3 Axes vertical precision center. Titan 1003 is a perfect l machine for performing fast and precise 3-axis machining.

Request information

3 Axes vertical precision center. Titan 1003 is a perfect l machine for performing fast and precise 3-axis machining.

Request informationTitan 1003 is a milling machine totally designed, developed and produced in Italy, perfect for making fast and precise 3-axis machining. Titan 1003 is equipped with a structure that, thanks to the damping capacity of its frame, is able to absorb all vibrations, allowing a high quality in the surface finish.

Titan 1003 is compact, accurate and cost advantageous!

Upon request, it is possible to customize Titan 1003: up to 36000 rpm.

The machine is able to perform roughing and fi- nishing functions of 3d surfaces, in addition to drilling, boring, tapping and interpolated threa- ding processes. Versatile and compact, Titan 1003 is able to realize pieces with high accu- racy and high-quality finishing in a rapid, easy and competitive way.

Titan 1003 is able to easily work steel, light al- loys and plastic materials; the main applica- tions, due to the spindle’s high speed, are com- ponents and moulds made out of aluminium and plastic materials processing.

Components: Moulds

Material: Stainless steel

Performed process: Drilling and incision

Tool: Cutter

Components: Structural components

Material: Aluminium 7075

Performed process: Interpolation drilling D18.0 -0.0 +0.01. Rectangular hollow W20.0 -0.0 +0.02

Tool: Cutter D18

Components: Buckles, clasps..

Material: Brass, zamac

Performed process: Milling, drilling, incision, threading

Tool: Cutter

Titan 1003 is appropriate for all the manufacturing companies related to the high-end fashion world.

Small and compact, it has been created to be placed in labs and workshops. Buckles, clasps and clamps are just some of the components that the machine is able to realize. Titan 1003 can be equipped with specific overturning vices to enhance the precision of the processed pieces, reducing production time. It is possible to integrate Titan 1003 with loaders and automatic storage system in order to produce 24 h a day.

Components: Moulds

Material: Stainless steel

Performed process: Drilling and incision

Tool: Cutter

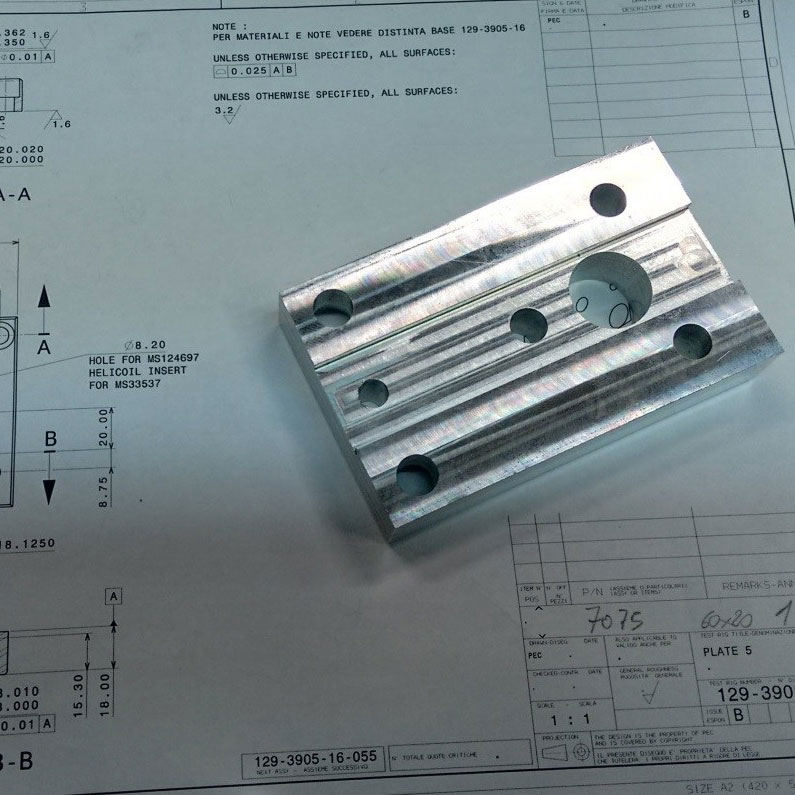

Components: Structural components

Material: Aluminium 7075

Performed process: Interpolation drilling D18.0 -0.0 +0.01. Rectangular hollow W20.0 -0.0 +0.02

Tool: Cutter D18

Components: Buckles, clasps..

Material: Brass, zamac

Performed process: Milling, drilling, incision, threading

Tool: Cutter

Titan 1003 is appropriate for all the manufacturing companies related to the high-end fashion world.

Small and compact, it has been created to be placed in labs and workshops. Buckles, clasps and clamps are just some of the components that the machine is able to realize. Titan 1003 can be equipped with specific overturning vices to enhance the precision of the processed pieces, reducing production time. It is possible to integrate Titan 1003 with loaders and automatic storage system in order to produce 24 h a day.

The numeric control is specifically designed for Titan 1003, the software is focused on the 17inch touch screen interface limiting the physical buttons only to the useful commands. It adapts to every automatic necessity of the industrial field, removing the PLC from the machine cabinet.

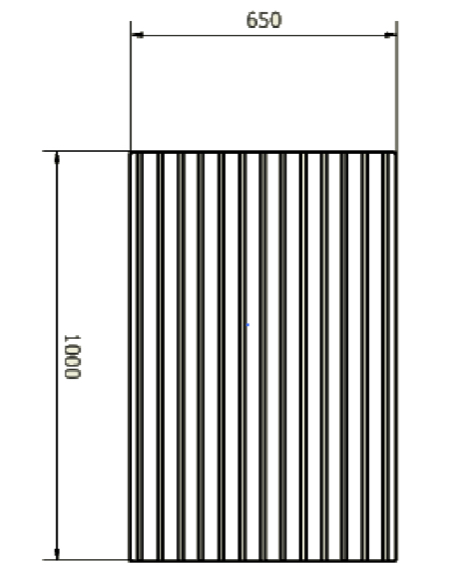

| Working Area | Axis X | 1000 mm |

| Axis Y | 500 mm | |

| Axis Z | 500 mm | |

| Spindle Line | Spindle speed | 24.000 spindle / min (36.000 Option) |

| Spindle power | 5,5 kW (7,5 kW Option) | |

| Spindle type | Electro spindle | |

| Spindle cone | ISO BT30 (Option HSK A40, HSK E40, HSK E32, ISO 30 ) | |

| Change Tools | 12 Positions | |

| Spindle taper | Pneumatic tool change | |

| Automatic tool change | ||

| Feeds | Rapid feed | 20.000 mm/min |

| Working feed | 12.000 mm/min | |

| General Data | Total installed power | 10 – 12 Kw |

| Footprint | 2000 mm X 2300 mm | |

| Machine Height (including base) | 2600 mm | |

| Standard accessories | Numeric Control | Delectron (Option: Heidenhain, Siemens) |

| Electronic leaflet | ||

| Touch screen operator interface, assisted programming | ||

| Tank for collecting chips | ||

| Guides | Roller on all axes | |

| Optical Scales | 1um (0.5um Option) | |

For all our machines, it’s possible to develop Customized Automation for the part loading and handling part, pallet handling and other customized and unique solutions.

Find how